Application

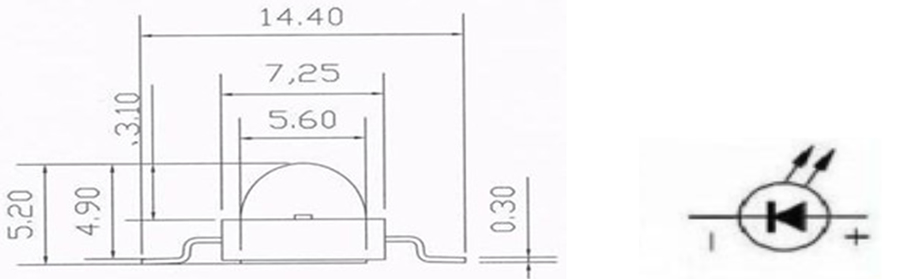

2.External dimensions and equivalent circuit

3.Classification and characteristics

3-1. Absolute maximum rating

3-2. Photoelectric characteristic

3-3.Degradation curve

3-4.(TYP) Characteristic diagram

4. Reliability

4-1. Test items and conditions

4-2. Failure criterion

5.The inspection items and standard defect

6. Warning

1.:Application: decoration, lighting High power1W led.This specification is only applicable to models for imitation lumens are white High power LED 1W

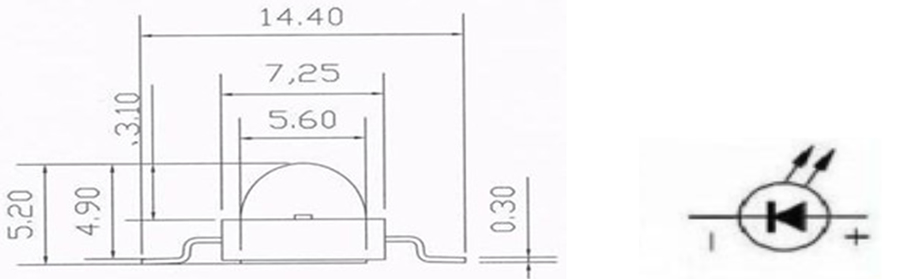

2.:External dimensions and equivalent circuit:

Company:mm Without tolerance indication for all:±0.02mm

3Classification and characteristics:

3-1.Absolute maximum rating

|

Project

|

Symbol

|

Value

|

Company

|

|

Limit power

|

P

|

1.3

|

W

|

|

Forward current

|

IF

|

350

|

mA

|

|

DC reverse voltage

|

VR

|

5

|

V

|

|

Working temperature

|

TOPR

|

-30~+60

|

℃

|

|

Storage temperature

|

TSTG

|

-35~+100

|

℃

|

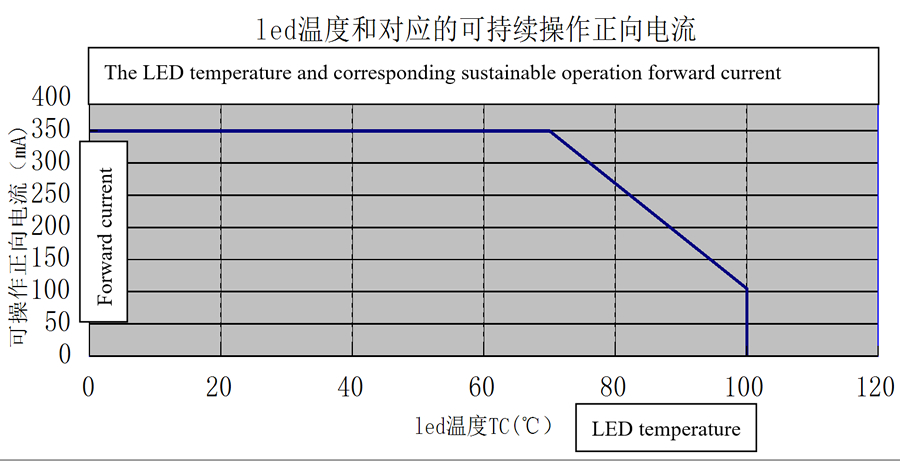

1. led。

Ultimate power and the forward current refers to the LED light source temperature by use of suitable radiator under maximum setting.

2. led。The initial connection error reverse voltage, beyond what would be possible damage to the High power LED

3. led。Not the same as the temperature (the next page of the corresponding temperature test point) represents a LED light source according to the next page degradation curve corresponding to the data operation.

3-2.Photoelectric characteristic:Tc=25 ℃,IF=350mA

|

Project

|

MIN

|

TYP

|

MAX

|

Company

|

|

The positive DC voltage(VF)

|

3.0

|

3.2

|

3.4

|

V

|

|

Luminous flux(Φ)

|

120

|

128

|

135

|

lm

|

|

Color temperature(CCT)

|

5000

|

5200

|

5500

|

K

|

|

(Ra)

|

70

|

71

|

75

|

|

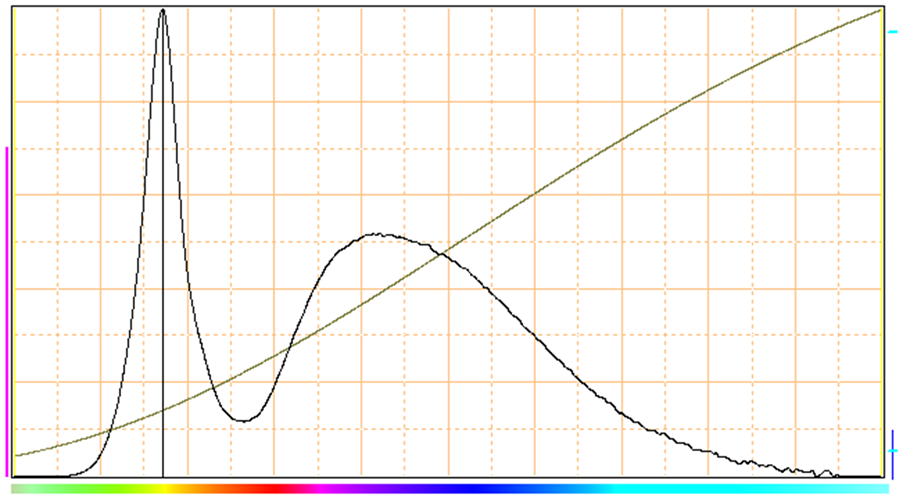

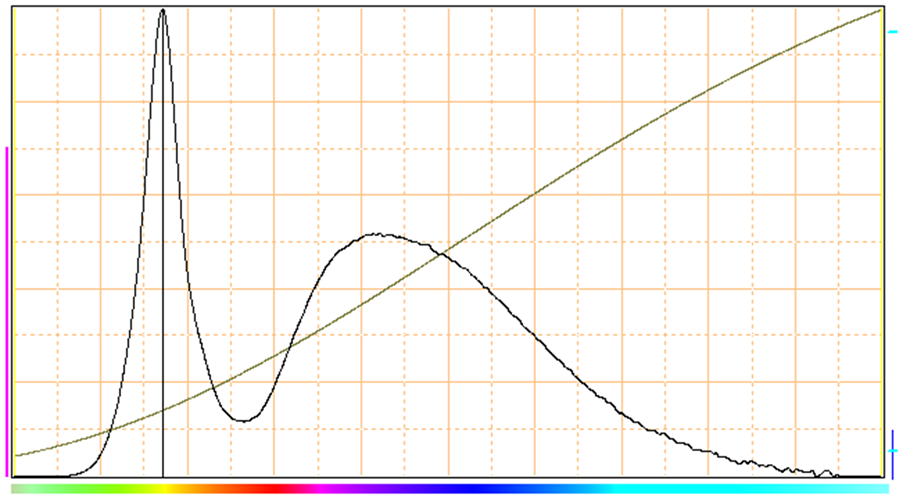

Led Led spectra:

Tc=25 ℃ IF=350mA 5000-5500k

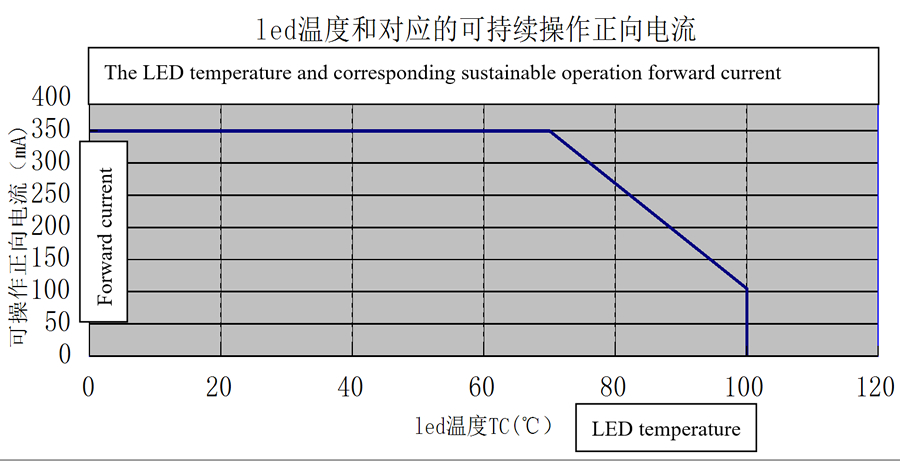

3-3.Degradation curve:

Note: in order to keep the temperature below the rated, the need to ensure that adequate heat dissipation performance of radiator

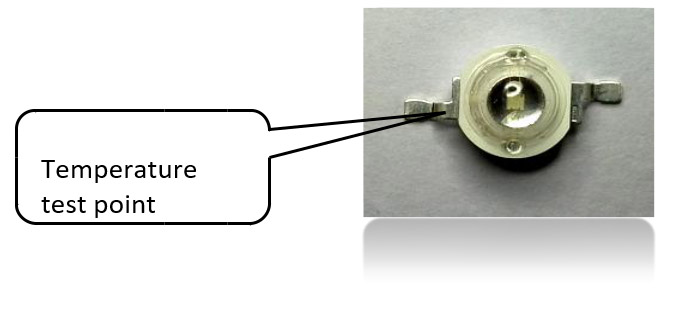

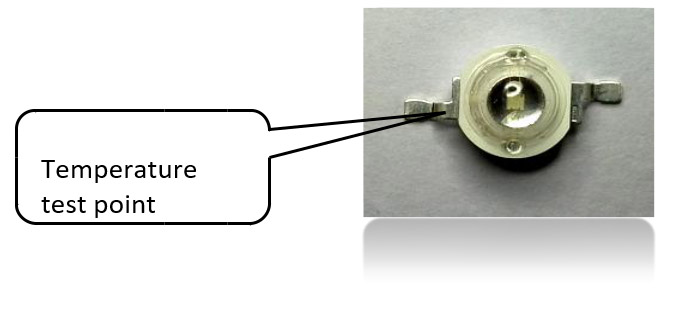

1W high power Led Temperature test point:

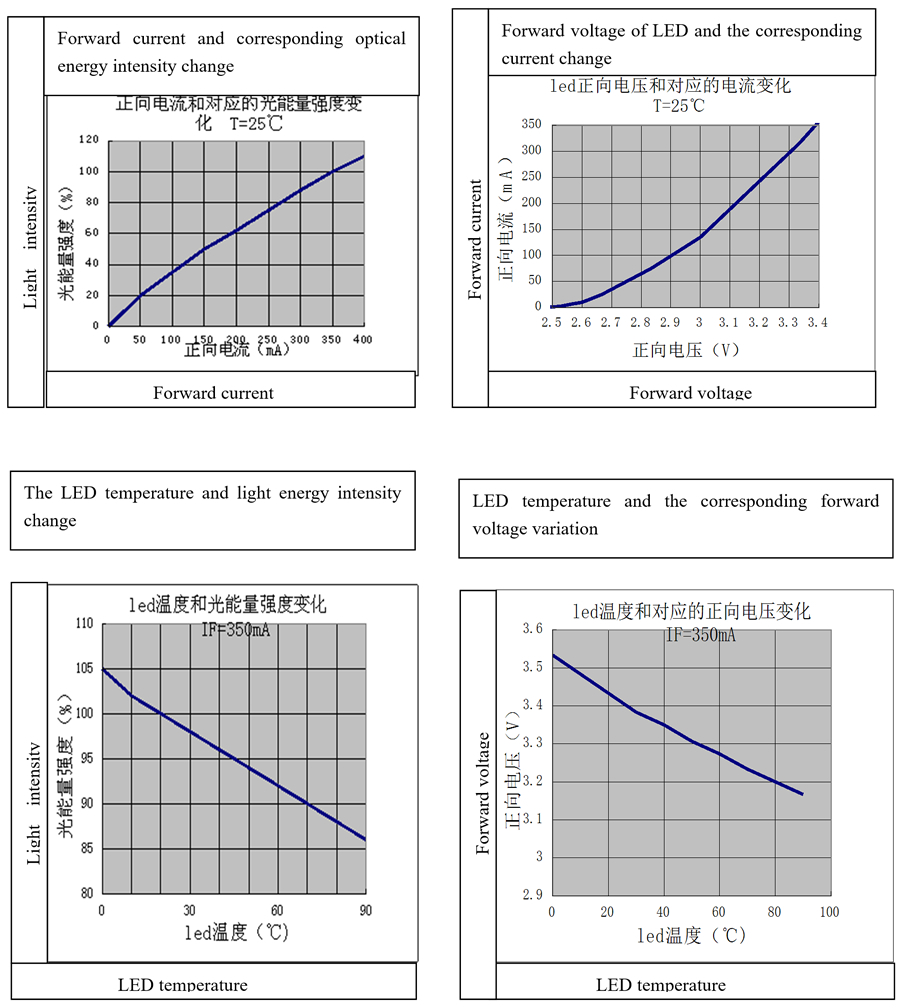

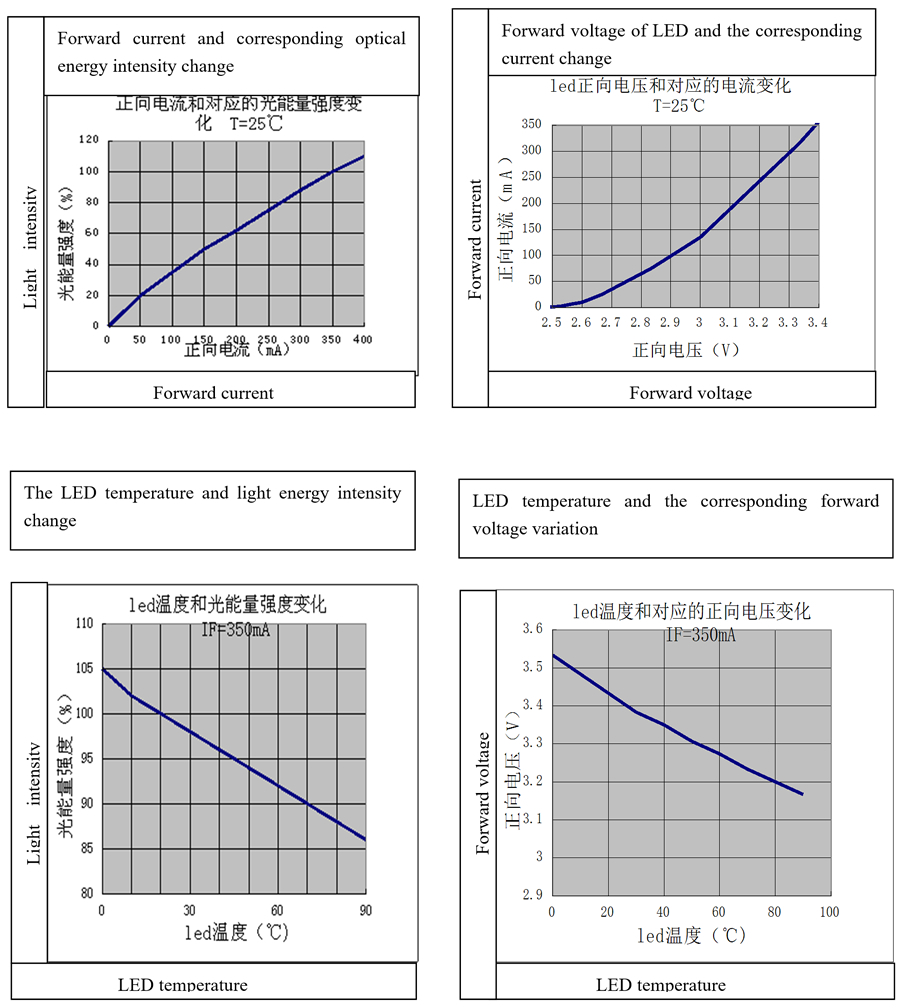

3-4.Characteristic diagram (TYP)

Note: this page stated the characteristics of the data for reference only (without the guarantee of data)

4. Reliability:The reliability of the product will meet the following items

4-1. Test items and conditions

|

Serial number

|

Test item

|

Test conditions

|

Number of samples

|

Failure number

|

|

1

|

High and low temperature impact

|

25℃(30min)+100℃(30min)→25℃(30min)-35℃(30min),50cycles

|

10

|

0

|

|

2

|

High temperature storage

|

+100℃,100h

|

10

|

0

|

|

3

|

Low temperature storage

|

-35℃,100h

|

10

|

0

|

|

4

|

High temperature and high humidity storage

|

T=+60℃,RH>=90%,100h

|

10

|

0

|

|

5

|

High temperature operation

|

T=+80℃,IF=350mA,100h

|

10

|

0

|

|

6

|

Low temperature operation

|

T=-30℃,IF=350mA,100h

|

10

|

0

|

|

7

|

High temperature high humidity operating

|

T=+60℃,RH>=90%,IF=350mA,100h

|

10

|

0

|

4-2. Failure criterion:

|

Serial number

|

Parameter

|

Failure criterion

|

|

1

|

|

LED no radiation

|

5. The inspection items and standard defect

|

Serial number

|

Project

|

Negative standard

|

Classified

|

|

1

|

Radiation

|

(LED)Luminescence (LED no optical radiation)

|

Major defect

|

|

2

|

-Electronic and optical properties

|

Is not in conformity with the specifications (forward voltage, flux and color coordinate range)

|

Minor defect

|

|

3

|

Outside dimension

|

With the specified size mismatch (described on page second of the peripheral dimensions and tolerances.)

|

|

4

|

Appearance

|

,1mmForeign body, scratches or luminous range of diameter 1mm bubble

0.2mm2.5mm Luminous range 0.2mm long 2.5mm

Fiber connection end foreign body

:The substrate edges: exceeds the specified size

|

6. Warning

Storage conditions: please follow the following conditions:

*:5~30℃,60%。(led15)

Open the front: temperature of 5~30 ℃, relative humidity is lower than 60%.(open High power LED should be within 15 days of use.)

*:5~30℃,60%。(24)

Open: temperature of 5~30 ℃, relative humidity is lower than 60%.(24 hours of soldering)

After opening the High power LED should be placed in the waterproof alumina absorbing packaging materials (silica gel)

Avoid contact with corrosive gases, such as exposure, electrode surface will be damaged, can affect the soldering.

Conditions of use: This product design is not directed against any of the following conditions

As in any of the following conditions using the product, please determine its normal performance and reliability.

(C1,H2S,NH3,SO2,NOX,)

Wet with dew, frost, salt air, corrosive gas in place (C1, H2S, NH3, SO2, NOX, etc.)

Exposure to the sun, outdoor exposure, dusty place.Water, oil, medical liquids and organic solvents

Cooling: if High power LED light using beyond a specified forward current, can damage the 1W High power LED inside the chip or or burned black phenomenon.

Please use the appropriate body, in order to avoid High power LED memory in too much heat.

Installation: installation error, there will be a short crack sheet or high temperature cooling bad etc.Please pay special attention to installation method.For more information please refer to the following matters needing attention in installation:

Heat conducting glue, plastic or special connectors mounted radiator.Such as using only the thermal conductivity of plastic or rubber, please check before installation effectiveness and reliability.Led because of heat and quench, abnormal temperature increase may lead to terrible consequences, including the equipment damage, solder drop and the phenomena of smoking.

*led,

When 1W High power LED is mechanically mounted, attention due to withstand the pressure and failure.Avoid the use of flat plate.

Suggest using highly heat bonded to the plate in order to effectively dissipate heat.

*,。

Please in the early and long-term attention bonding plate color change effect, because of back reflection changes induced by light emitted and the color of the light.

ledLed tension

led。led。

LED surface is limited by the mechanical tension.The High power LED outer lens applied pressure causes colloidal and internal damage.No pressure on the surface of the lens component.

A: PC

Connection method: such as the use of welding method, please according to the following methods:

*(380℃),3.

The use of anti-static automatic constant temperature soldering iron (the highest temperature is 380 ℃) welding, each place not more than 3 seconds.In the entire pad full welding, solder to full.

Avoid using solder touches the lens portion * this product is not suitable for reflow soldering

*Please smooth soldered to each electrode

*Please avoid contact colloid generated instability phenomenon

*Reflow soldering: Compatible with infrared and vapor phase reflow solder process

Electrostatic: This product is sensitive to static electricity, please take measures to deal with, if necessary please install protective circuit.

⑧Starting method

When the 1W High power LED when in working, no reverse voltage can not be applied to High power LED.

When not working any backward and forward voltage can not be applied in the module.

Energy supply recommended the use of constant current driver.

⑨Clean

Lens surface impurities as far as possible with a soft cloth wipe, avoid scratch the lens, if necessary, cleaning, use a soft cloth dipped volatile alcohol cleaning.

⑩ Safety

If there is excessive current, there will be serious consequences such as: abnormal temperature, smoke, fire, careful handling of excessive current and voltage

As with welding connection method, may cause thermal damage, please use caution to prevent contact wire, caused by short circuit or leakage.

Please ensure that the use of the equipment to comply with the national safety standards and regulations.

Users in the operation which view the work in the 1W High power LED should wear glasses, and don't open High power LED , in addition, the operator should not watch from LED reflected light for more than 60 seconds.